which hardness test uses the steel ball as indenter|rockwell hardness testing scale : wholesalers The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) . See more WEB22 de jan. de 2024 · Banks like Chase, Bank of America, Citigroup, Goldman Sachs, and PNC support gambling payments. Wells Fargo doesn’t follow a one size fits all approach, with several users saying they .

{plog:ftitle_list}

webEstes são os convocados e os alinhamentos do Sporting Braga vs Fiorentina - Conference League 2023

The 45N scale employs a 45-kgf load on a diamond cone-shaped Brale indenter, and can be used on dense ceramics. The 15T scale employs a 15-kgf load on a 1⁄16 -inch-diameter (1.588 mm) hardened steel ball, and can be used on sheet metal. See moreThe Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) . See more

The differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary dimensionless number.• Except for testing thin materials in accordance with A623, the steel indenter balls have been . See more

• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more

• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See more

The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as: where:First, a preliminary test force (commonly referred to as preload or minor load) is applied to a sample using a diamond or ball indenter. This preload breaks through the surface to reduce the effects of surface finish.

rockwell hardness testing scale

how to test if paint is oil based

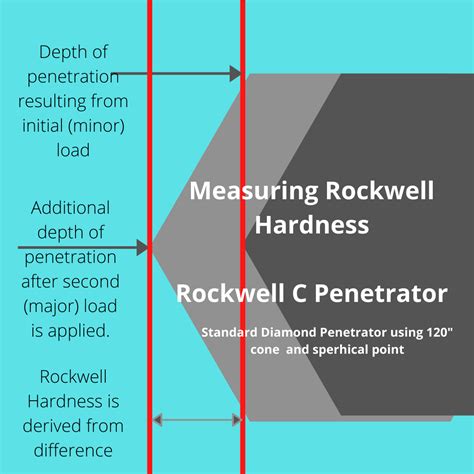

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the .The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry. In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation .

The indenter used in the Brinell test method is made of a hard metal ball of diameter D = 10; 5; 2.5 or 1 mm. It is applied to the specimen with a test force (to standard from 1 kg to 3000 kg) and held according to the holding time.Superficial scales HRN (diamond indenter) and HRTW (ball indenter) have a preliminary test force of 3 kgf (29 N) and total test forces of 15 kgf (147 N), 30 kgf (294 N), and 45 kgf (441 N). The Superficial Rockwell hardness test is a . The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .

ASTM E18 is a standard test method used to determine the Rockwell hardness of metallic materials. Rockwell hardness is a measure of a material’s resistance to indentation, similar to .HRE 1/8” diameter tungsten carbide ball indenter, 100 kgf major load; HR30N (Superficial Rockwell 30N-scale): Diamond cone indenter, 30 kgf major load . The Rockwell hardness test is used for macro hardness tests, which are .

ms paint online test in hindi

Which hardness test uses the steel ball as indenter? The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm. This is applied under a load P of 500–3000 kg applied for 10–30 s.

K – constant, 130 for steel ball indenter and 100 for diamond indenter. Table 3-6 Test Specification and Application of Rockwell Hardness. Ruler: Type of indenter: Initial test force/N: Main test force/N: . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended.The manufacturer of hardness testing equipment uses steel -ball indenters to penetrate metal that is being tested. However, the manufacturer thinks it would be better to use a diamond indenter so that all types of metal can be tested. Because of differences between the two types of indenters, it is suspected that the two methods will produce .

For the Rockwell scales that use a ball indenter, either a steel or tungsten carbide (WC) ball indenter is permitted to be used in the test method standards of ASTM International and International Organization for Standardization (ISO). However, significant differences occur in Rockwell hardness tests depending on whether a steel or WC ball is .Rockwell scales that use a ball indenter, either a steel or tungsten carbide (WC) ball indenter is permitted to be used . accurate measurement of the hardness of ball races [1], the Rockwell hardness test has been expanded from the original Rockwell B hardness scale which uses a 1.588 mm (1/16 in.) diameter ball indenter, to other hardness .Explanation: Brinell hardness test uses a hardened steel ball as an indenter. It is 10 mm diameter ball. Diamond indenter is used in the Rockwell test. 2. What test force is applied for nonferrous materials in Brinell test? . Explanation: Brinell hardness test uses ball indenter. Its diameter is kept 1 mm for lower load 1 kgf. It is taken 10 .

An indentation hardness test using a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter, under specified conditions, into the surface of the material under test, and to measure the difference in depth of the indentation as the force on the indenter is increased from a specified preliminary .The manufacturer of hardness testing equipment uses steel-ball indenters to penetrate metal that is being tested However, the manufacturer thinks it would be better to us diamond indenter so that all types of metal can be tested Because of differences between the two types of indenters, it is suspected that the two methods will produce diffe hardness readings.The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.We offer a wide range of ball indenters as well as loose balls and caps for Brinell and Rockwell hardness testing. Our ball indenters are available in Tungsten, Carbide or Steel. They come in different sizes, as well as with or without a certificate included. . Tungsten Carbide Ball Indenter (6) CERTIFICATION . 1/16" Steel Balls | Qty 50 .

The manufacturer of hardness testing equipment uses steel-ball indenters to penetrate metal that is being tested. However, the manufacturer thinks it would be better to use a diamond indenter so that all types of metal can be tested. .

Therefore, the relative ∆HRB measurement values between a deformable steel or WC ball and a rigid non-deformable ball can be calculated from, 0.002 mm ∆h ∆HRB ~ = (9) where ∆h ~ is in mm. 3.1 Ball indenter deformation From Eq. 3, it can be seen that the deformation of the indenter ball contributes to the HRB measurement value.

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. Cone indenter: 120°

The manufacturer of hardness testing equipment uses steel-ball indenters to penetrate metal that is being testod. However, the manufacturer thinks if would be better to use a diamon indenter so that all types of metal can be tested. Bocause of diflerences between the two types of indenters, it is suspected that the two methods will produce .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Gilmore Diamond Tools’ manufactures diamond indenters and penetrators for all makes and models of Rockwell hardness testing machines – as well as custom indenters for use in difficult testing situations. . Carbide Test Diamond Indenter - Newage Indentron and Indentec Testers: 205: . Replacements balls are available for our 1/16”, 1/8 .Explanation: There are many scales on which Rockwell hardness tests can be conducted. The B-scale uses a 1/16 inch diameter steel ball indenter. The C-scale uses a diamond cone indenter of 120 degrees, which is named as BRALE.

Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. . 9100405 - Rockwell indenter 1/16" WC ball with 4 spare balls, ASTM, ISO and JIS certified; 9100406 - Rockwell indenter 1/8" WC ball with 4 spare balls, ASTM, ISO and JIS .Mitutoyo Steel Ball Indenter. These steel ball indenters are for use with the Mitutoyo Rockwell and Rockwell Superficial type hardness testing machines. Select from the options below: 1/16" Diameter Steel Ball Indenter (64HAA118) 1/8" Diameter Steel Ball Indenter (64HAA121) 1/4" Diameter Steel Ball Indender (64HAA123) 1/2" Diameter Steel Ball .Which hardness test uses the steel ball as indenter? a.Rockwell C hardness test b.Brinell Hardness test c.Rockwell B hardness test d.Vickers hardness test. There are 2 steps to solve this one. Who are the experts? Experts have been vetted by Chegg as specialists in this subject. Expert-verified. Step 1. View the full answer. Step 2.

rockwell hardness testing methods

how to test if paint is oil or latex

Resultado da 8 de jan. de 2024 · Caroline Ferreira da CNN. São Paulo. 08/01/2024 às .

which hardness test uses the steel ball as indenter|rockwell hardness testing scale